Keder

What is Keder?

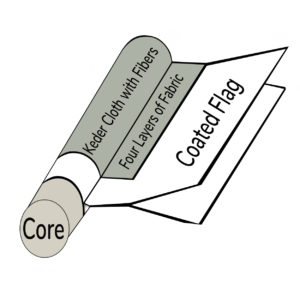

Keder is a rope-edge product that connects fabric panels to a frame, by sliding it into an aluminum extrusion rail. Foundationally, compromising of two components: a PVC extrusion core, and fabric. The fibers of the fabric are exposed on the outside, making the cord easier to slide into the frame. Combining the rope edge to the fabric panel, making keder easier to install than other rope edges.

Keder rope is versatile posing into a variety of different applications. Therefore, we carry a variety of products in our Kedermaker and Eurokeder catalogs. Contact us to identify the products best for your project. Below are many ways keder is integrated into our infrastructure.

Tent Structures

Keder acts as a strong reliable connection between the fabric panels and the railing/frames systems in tensile and tent structures, being permenant or temporary structures. Lightweight specializes in supplying materials for repairing fabric panels in tent structures.

Banner Advertising

Capable of acting as a support system for various advertising banners and signs. Durability and easier installation make our keder ideal for this type of application.

Awnings and Sunshades

Keder and extrusions rails systems secure awning fabric for smaller-scale outdoor spaces producing increased UV resistance from the sun.

Marine

Applying keder as boat covers and sails offers many benefits including a quality of life improvment to any marine application. For this reason, our keder does not compromise between its flexibility and durability.

Which type of Keder is best for my project?

Style

Keder style separates into three forms based on their attachment method: sewing, single-flag weldable, and double-flag keder.

Sewing

Sewing flag is the simplest of the three to attach. Welding the flag shut, making it easy to sew to a fabric panel. A great choice for signs and banners, but also, for larger applications such as awnings and canopies.

It is important to note that most sewing thread is not designed for UV-resistance and thus this is not a suitable method for durability, especially against sunlight exposure, is an attribute in your consideration. Special PTFE thread can offer long-term durability.

Single Flag Keder

A single flag attaches with any welding method, including hot air welding, wedge welding, and radiofrequency welding (RF welding for short). RF welding creates a stronger bond and improves water tightness and UV resistance. The single flag is not appropriate for larger panels with high tensile loads because of the welding occurring on one side, the weld becomes a single point of failure. This is why single flag uses wider 20mm welds, and why our experts recommend using RF welded single flag Keder. Lightweight distributes all keder already RF welded.

Double Flag Keder

Double-flag is the strongest and most durable, and only welds properly using a radio-frequency (RF) welder, which can be cost-prohibitive for smaller companies. The weld is no longer a point of failure because both sides of the flag welding to the panel make the strength of the fabric its only limitation.

Weave Styles

The weave style refers to the way the keder fabric is woven. There are two common weaves: plain weave and the panama style weave.

Plain Weave

Plain weave is the most basic form of weaving. Each weft yarn crosses the fill yarns up and under. The next weft yarn goes over the fill yarn that the previous weft yarn went under and so on.

Panama Weave

Panama weave is a variation, whereby 2 yarns next to each other go up and under, as well in the weft as the fill direction. The Panama weave allows a greater strength of the fabric with the same yarn size storing more yarn per each inch woven

Thread Weight

There are different strengths when it comes to the thread, or yarn, that makes up the fabric. Fabric strength is measured using either Denier or the Dtex scale. Keder with thicker yarn tends to be stronger, more durable, and slides better, however, it also usually costs more. Lightweight Manufacturing offers three different thread weights: 2000 Denier, 1500 Denier, and 1000 Denier.

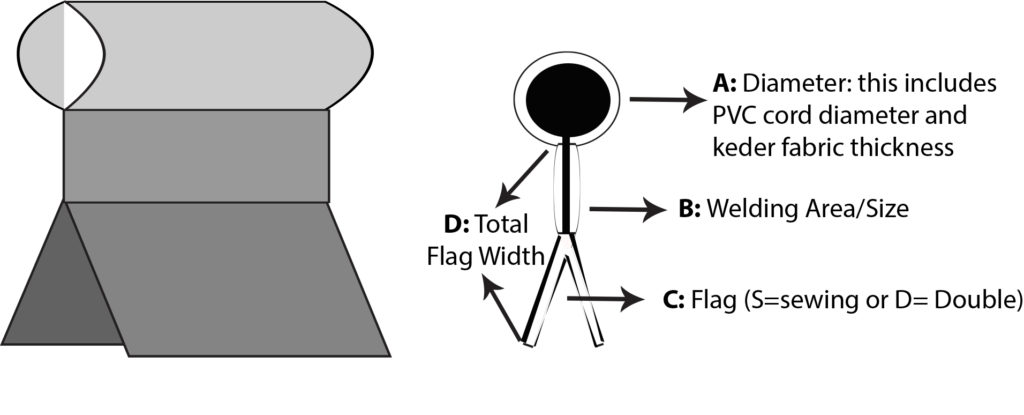

How do I know what size I need to order for my project?

Keder extrusions (also known as keder rails) are aluminum extrusions designed to allow rope edges to slide into them, securing fabric panels in a way that is safe and efficient. Allowing the integration of fabric panels into almost any frame with minimal alterations. The rails can offer solutions for awning and shade, tenting and structures, curtains, as well as banners and billboards. Placing your order with our team of experts noting that you would like keder rails with your order and Lightweight will include the cost in your quote.