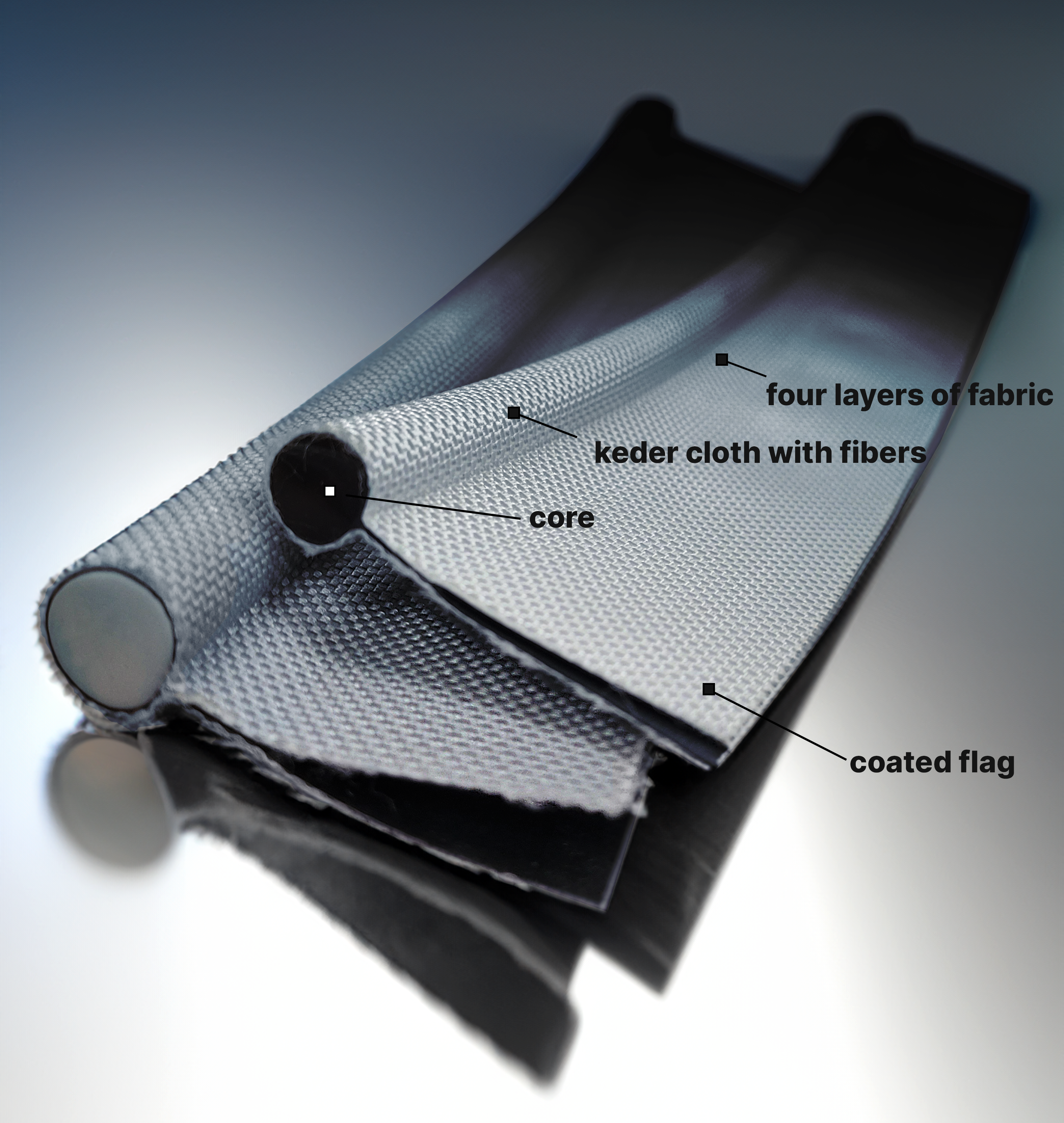

Double-Coated Keder

Stronger lasting keder.

Double Coated Keder is the result of wrapping 24oz PVC-coated fabric around an extruded core and adding a layer of traditional keder fabric on top without covering the flag. This specific keder creates a durable strong bond that makes the core capable of sliding into extrusions rails easier and provides a longer lifespan for the keder. Eurokeder a european clearspan manufacturer provides products using this specific kind of premium grade keder.

Advantages for Permanent/ Semi-Permanent Structures

UV-Resistance: Since double coated keder has regular fabric underneath the keder cloth UV degradation of the keder cloth does not impact the longevity of the fabric structure. Compared to regular keder cloth which is less UV-resistant than typical architectural fabric since there is no coating to protect the fibers.

Coated flag: the flag has a regular architectural coating, white opaque, and any accessories welds directly to the flag. The most common accessory to benefit is a beam flap, capable of narrowing for a crisper finish of the fabric structure.

Advantages for Rental Structures

Resistance against wear where regular keder wears first. Where the keder slides against the edge of the keder track, there is a double layer of fabric. Additionally, this greatly increases the resistance of the keder against wear. Consequently, making the panels last longer.

Coated flag: the flag has a regular architectural coating. It is easy to clean, and any accessories can be welded directly to the flag. If the keder would be damaged, it can be cut off and new keder can be welded directly to the flag.